sa 105 impact test|sec sa 105 flange : exporting B31.3 and ASME Section VIII indicates SA-105 material (for a flange, in this case) has a MDMT of -20 F. However, B31.3 allows for some materials to be used as low as -155 F . Ran'jit's father commanded a familiar as well, but when he was slain by a sin eater, Huracan somehow survived, and has been seen on several occasions since. One theory posits .

{plog:ftitle_list}

Resultado da 24 de mar. de 2022 · Bruna Linzmeyer muda o visual (Foto: Reprodução/Instagram) Bruna Linzmeyer radicalizou o visual. Nesta quinta-feira (24.03), a atriz usou suas redes sociais .

UCS (in particular UCS-66) has required impact testing for both my SA 516 and my SA 105 materials. I am now trying to figure out what are acceptable values for the impact .Impact Test – A Charpy V-notch impact test is a dynamic test in which a notched specimen is struck and broken by a single blow in a specially design testing machine. The measured test .

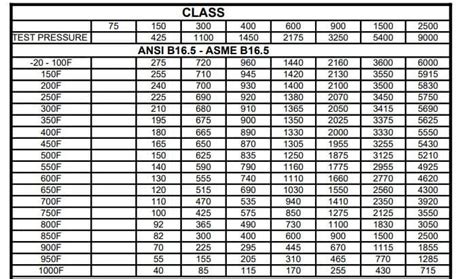

Based on industry experience with SA-105 flanges having poor low-temperature toughness properties, the 2019 edition of ASME VIII-1 introduced more stringent requirements for impact . B31.3 and ASME Section VIII indicates SA-105 material (for a flange, in this case) has a MDMT of -20 F. However, B31.3 allows for some materials to be used as low as -155 F .

SA-350: Impact testing is mandatory. SA-105: Impacting test is not mandatory, but if done, minimum design metal temperature (MDMT) could be reduced. 4. Heat Treatment.The SA-105 MDMT curve change is probably the most impactful change to code users in the 2019 coded that will take effect in 2020. It’s a simple issue, but with complex consequences. In 2017 and earlier editions of the code, SA-105 was .

available, then one tension test from each heat is required instead of one test from each heat in each heat-treatment charge. The test specimen material shall be included with a furnace charge. 7.3.3 Testing shall be performed in accordance with Test Methods and Definitions A 370. The largest feasible round ⁄⁄ A 105/A 105M – 03SA-350: For low-temperature service with Charpy V-notch impact testing. SA-105: For Ambient and higher temperature service. 2. Manufacturing Process. . SA-105: Impacting test is not mandatory, but if done, minimum design metal temperature (MDMT) could be reduced. 4. .

E. Hydrostatic Test :- 1. Forgings manufactured under this specification shall be capable of passing a hydrostatic test compatible with the rating of the finished item. Related Keywords • asme sa 105 pdf • asme sa-105 pdf • astm a105 pdf • astm a105 pdf download • astm a105 18 pdf • astm a105 chemical composition • astm sa105 pdf

This interpretation provides guidance on changes to ASME Section VIII regarding the use of SA-105 flange materials in pressure vessel construction. SA-105 flanges now have more stringent impact test requirements due to their poor low-temperature toughness properties. The material has been reassigned from curve B to curve A in Figure UCS-66, affecting impact test . A/SA-105 forged flanges supplied in the as-forged condition; . Therefore, if impact testing isn’t a possibility, the manufacturer must use a chemistry that is more restrictive than the chemistry allowed by the control limits listed in individual material ASTM/ASME specifications to prevent brittle fracture and SCC . Minimum Tensile Strength: 70,000 psi (485 MPa) ; Minimum Yield Strength: 36,000 psi (250 MPa) ; Minimum Reduction of area (0.2 % offset method or the 0.5 % extension-under-load method ): 30% ; Maximum Hardness: HBW 197.The usual hardness range for ASTM A105 carbon steel forge material is 137 to 197 HBW. Impact Test 2번째 포스팅 입니다. 이번에는 Impact Test의 요건에 대해 알아보려 합니다. 다소 긴 내용이 될 수 있지만, 차근차근 읽어 보시는걸 추천 드립니다. . A/SA-105 forged flanges supplied in the as-forged condition. Curve B. Curve B .

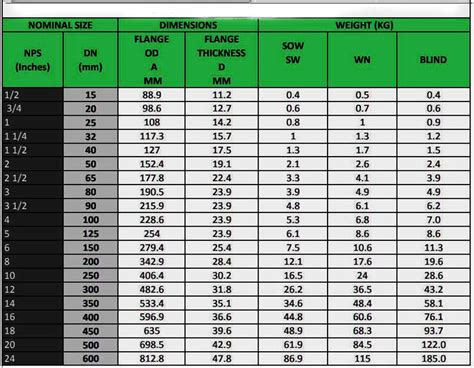

Impact test; Ultrasonic test; Tensile test; NPT Tapered: Female thread; Male thread; Finish Type : Polished; Marking Info: Standard; Size; Working pressure . NPT/ BSPP 3000 LBS A105 Threaded Fittings Dimensions and Burr-free SA-105 UNS K03504 Hex Nipple Wall Thickness according to ANSI B16.11. ASTM A105 Tee Dimensions (NPS) Bore Of Socket .

Haze Meter service

sec sa 105 flange

mechanical requirements of the material specifications. Further testing has found some of these flanges have extremely low impact test values at -18°C (0°F) and warmer temperatures. However, it has also been reported that testing of some SA-105 flanges resulted in impact testing that was satisfactory well below the -29°C (-20°F) exemption.Rules for using materials below its MDMT without impact testing. The use of a material at a design minimum temperature colder than −29°C (−20°F) is established by para. 323.2.2 and other impact test requirements. For carbon steels with a letter designation in the Minimum Temperature column, the curve in Figure 323.2.2A of ASME B 31.3 .

I often see vessel components such as flanges, nozzle necks and main chambers made from SA-105, SA-53 or SA-106B Pipe. The ASME Code usually exempts these materials from impact testing down to -20F with some exceptions. As summarized in the articles referenced below, brittle fractures have been experienced at temperatures considerably warmer . I couldn't find any statement regarding impact test in Section2 A SA-179 as well as in SA-450 were as in PV elite it shows that it can be used with impact test up to -55°F , I have placed a material requisition requiring impact test report at . zulsaid; If the A 105 will be used at ambient temperature or above, I would not conduct CVN testing, it is really not necessary. IF there is a chance that the service temperature can reach -29 deg C and depending on the application, I would conduct CVN tests if the forging was supplied in an annealed condition.

It is just not safe to use SA 105 in a thick wall ASME VIII-2 vessel at -29 Deg. C ,so why look for impact test exceptions. RE: Self reinforce nozzle (SA105) for -29¦C (-20¦F) . It is possible to order SA 105N with impact test. Also, -29 deg. C is not a very low temperature and my experience says that impact will pass easily. This way, LF2 .

•SA-105 fittings and flanges supplied in the as-forged condition are now categorized as ASME impact test exemption Curve A. •ASME B16.5 & ASME B16.47 as-forged flanges are exempt from impact testing if the design temperature is no colder than 0°F. •Fittings and flanges that are normalized after forging are assigned Curve B. Impact testing was carried out on TINIUS OLSEN, USA make V-notch Charpy impact specimens prepared as per specifications in ASTM E23 standard [7]. Hardness testing was carried out on Shimadzu-HSV-30 Hardness tester with 1 kg load for test duration of 15 s. In order to understand the failed pipe specimens’ properties deviation from the . Generally, for A350 LF2 material flange, we will conduct low-temperature impact test according to the customer’s requirements, but for A105 flange, there is no relevant data for reference, so we suggest that the customer can avoid low-temperature impact test, and the mechanical property test is more in line with his requirements.. Finally, the customer took our .

In the above example (normalized SA 516 Gr.70, Curve D, 1.125 inch thickness), the minimum permissible temperature without impact test is -26 degree F.Eddy current testing sensitivity of ASME SA 105 Bright Bars: Excellent; Surface Integrity of A105 Carbon Steel Bars: Very Good; ASTM A105 Steel Round Bars Machinability: Very Good . Torsion test; Brinell hardness test; Impact test; Heat Treatment of A105 Round Bar. Completed projects. Rumaila Oil Field- UAE. Malaysian Oil & Gas Services .

Buy online ASTM A105 forged fittings available in 3000# to 9000# and BSPT, BSPP, NPT threads, directly contact SA 105 elbow manufacturer in India, and check sizes and price list.

B16.10 Face-to-Face and End-to-End Dimensions of Fer-rous Valves5 B16.11 Forged Steel Fittings, Socket Weld, and Threaded5 B16.34 Valves-Flanged, Threaded and Welding End5 B16.47 Large Diameter Steel Flanges5 2.5 ASME Boiler and Pressure Vessel Code: Section IX Welding Qualifications5 2.6 API Standards: API-600 Flanged and Butt-Welding-End Steel . Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads. These characteristics are vital for selecting materials that meet specific application requirements, resulting in safer and more .

sa 105 flange temperature limit

I am preparing drawings for charpy impact testing samples and have a question about what is the correct ASTM spec to call out for the plate. The product to be shipped to the customer has 1" SA-312 316/316L pipe that is to be welded to SA-105 socket weld fittings, designed to ASME B31.3.(b) When impact testing is necessary, the following toughness values are required. (1) If the specified minimum tensile strength is less than 655 MPa (95 ksi), then the required minimum energy for all specimen sizes shaIl be that shown in Figure 3.3 and Figure 3.4 for vessel parts not subject to postweld heat treat-ment (PWHT) and vessel parts subject to PWHT or nonwelded .1. The document discusses requirements for impact testing of materials according to ASME codes IX and B31.3. It outlines general guidelines, criteria for acceptance, test coupon preparation and testing procedures. 2. Tables and figures are presented showing minimum temperature limits for listed materials with and without impact testing, as well as .

Refractometer service

Resultado da Confira outros dias e aproveite os nossos prognósticos. Em breve as novas dicas de apostas estarão disponíveis. Na APWin você confere todos os palpites do Campeonato Argentina - Primera Division e mais prognósticos de futebol de graça de vários torneios!. Acesse já!

sa 105 impact test|sec sa 105 flange